and copper door and window enterprise,

striving to create buildings that move the world

The hot-rolling process gives the profiles a very special and unique texture, which amplifies the natural and raw character of steel. Signs of rolling and slight surface imperfections, which architects and designers call “beauty marks”, constitute the distinctive character of this material and make it very popular for profiles of particular slimness and elegance.

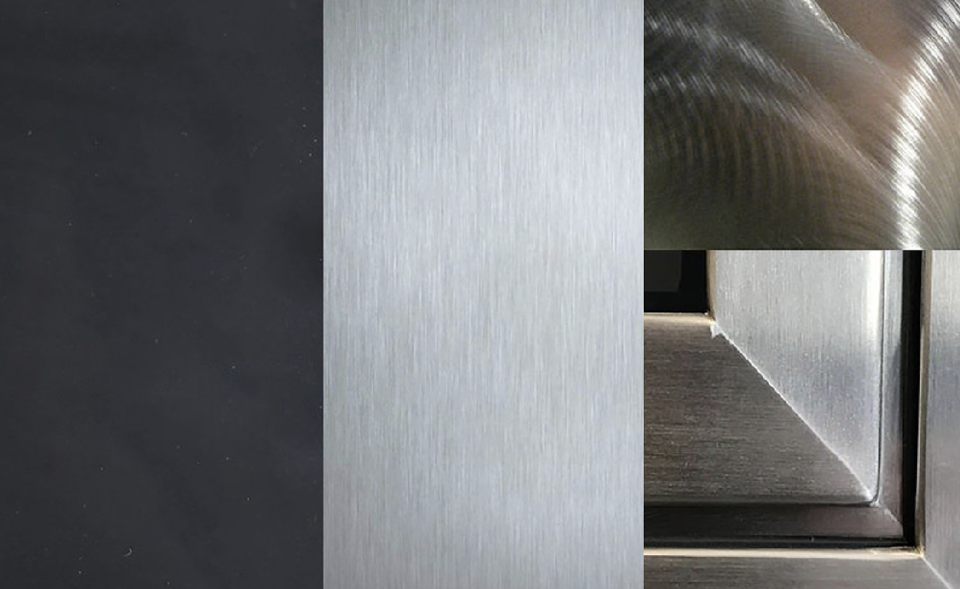

Windows and doors made from cold rolled steel profiles are usually coated with a zinc rich primer and then coated with one of the many RAL colors by powder or painted wet. Even though cold rolled steel profiles do not have the characteristic “beauty marks” of hot rolled steel, they still have a very distinctive texture, which is often underestimated.

Depending on the desired visual quality, the welds can be grounded flat, left natural or even emphasized by brushing or blackened with special patinas.

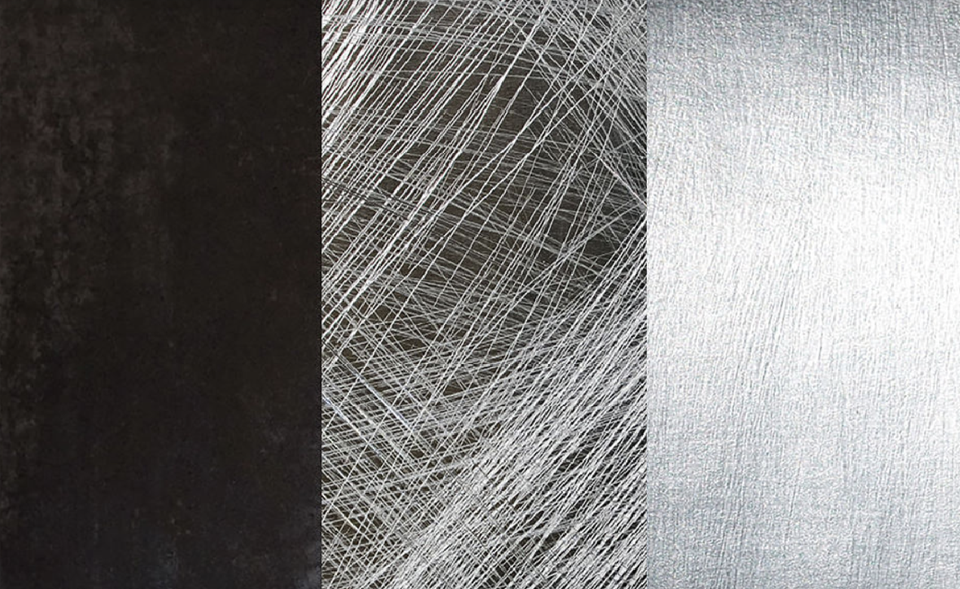

The technical properties and remarkable resistance over time make stainless steel a very popular material used in construction and architecture since 1920. Its exceptional characteristics allow its use even in areas subject to strong environmental aggression, for roofs, curtain walls, doors and windows of very long duration, in almost total absence of maintenance. Air pollution (industrial or volcanic), salt exposure (coastal or deicing salt), weather patterns (rain and humidity), design and cleaning frequency must be considered when using stainless steel. Our window and door profiles are all made from the more highly alloyed molybdenum containing stainless steel type 316/L (1.4404). For external application, we always recommend this “marine” type stainless steel with a smooth brushed or polished surface finish unless frequent cleaning is acceptable. In the last years, “black stainless steel” has become highly requested due to its natural texture. Similar to bronze this finish is achieved by applying special patinas on the brushed or bead blasted surface. Windows and doors with this black finish have a very distinctive and elegant character.

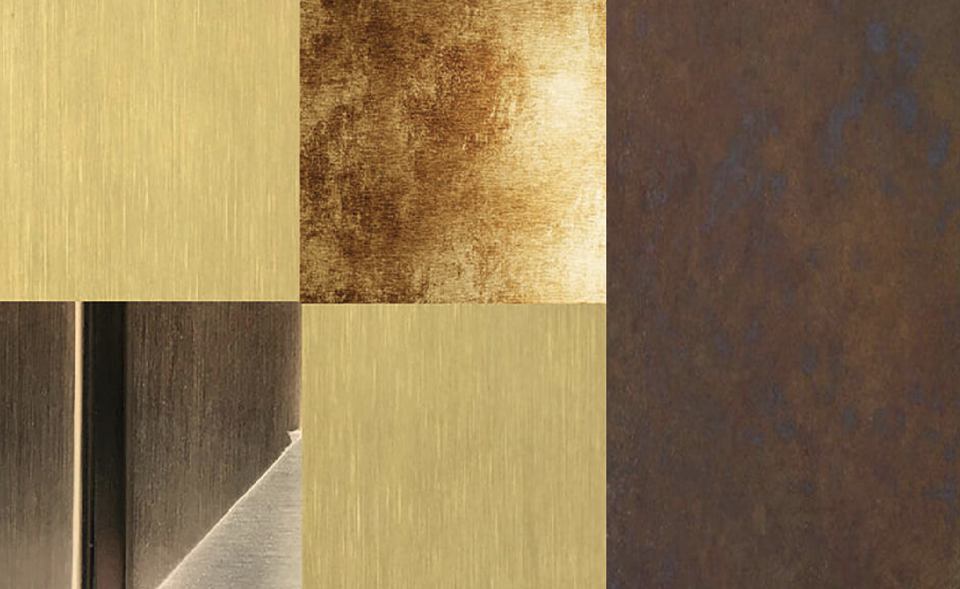

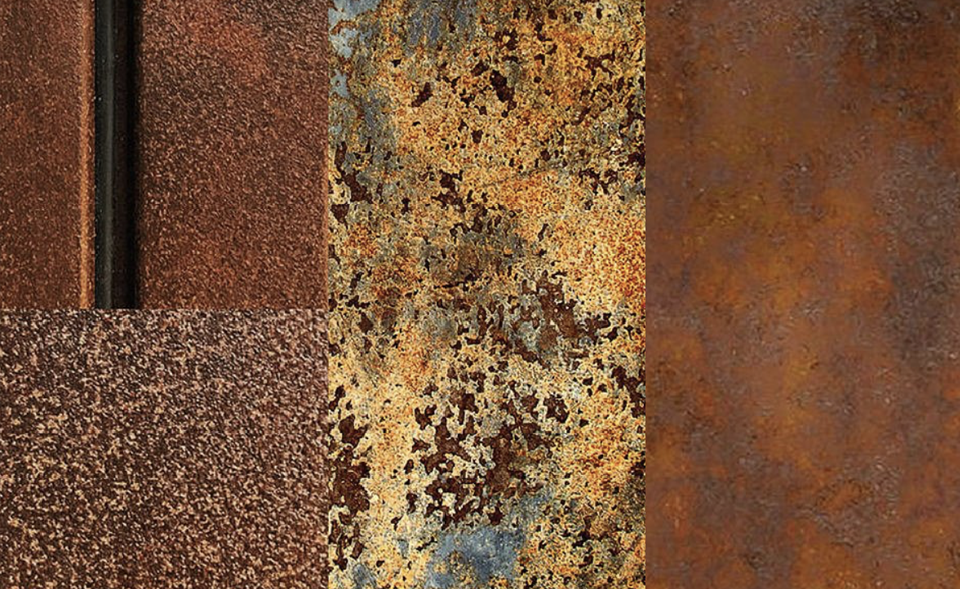

One of the most interesting trends in architectural materials of recent years is the increase in use of weathering steel – more commonly referred to by its trademark name, cor-ten. Though the material has been around for decades, it has seen a surge in popularity in the last decade. Originally used in restoration works, cor-ten steel is used nowadays in everything from private residences, boutique commercial and large institutional buildings. Cor-ten eliminates the need for painting. The product develops a thin skin of rust that actually protects the inner layers of steel from the elements. Usually window and door frames are treated with chemicals to accelerate the weathering process as the natural aging process could take several years before achieving this texture. Windows and doors made from cor-ten steel are both suitable for internal and external usage. Being a natural material, it will continuously react to rain or high humidity. This aging phenomenon is also known as “bleeding” and can be contained or avoided by applying periodically wax or oil, or alternatively by sealing the surface with a clear coat.

Windows and doors made from hot rolled steel profiles are usually, hot dipped galvanized, metallized (thermal zinc spray) or coated with a zinc rich primer. In the case of cold rolled steel profiles, especially with a thermal barrier, a zinc rich primer is the most common solution. This gives steel a long-term protection against corrosion and the ideal base to be coated with one of the many RAL colors by powder or wet paints. When it comes to color coating steel for contemporary architecture, architects and designers have shown a preference for darker colors with a grain texture or slightly weathered appearance. Classic black or white paints are often chosen to maintain the original character of the facade during heritage building renovations.

Bronze is one of the oldest metals known to man since the beginning of the Bronze Age over 5,000 years ago. It is considered a “living material”, subject to a natural oxidation or weathering and its colors range from a copper red fading through golden yellow to end in the different shades of classic browns. It emanates a warmness difficult to match with other metals. Contemporary architecture is rediscovering the value and beauty of this noble metal, which was the principal performer in windows and doors of representative commercial buildings and prestige residences of the 18th and 19th century.